The Dark Side of Chip Making has revealed an enormous carbon footprint. The US must address the dark side of chip making, now that the Science and Chip Making bill has become law.

As American semiconductor manufacturers grow the US Computer Chip industry, we will face new ecological challenges. Let us re-state that within the dark side of building the semiconductor industry, is a giant carbon footprint. This article is not meant as a criticism of the industry but as an alert. You will be seeing news as US companies accelerate the chip-making business in the near future. Do not allow the news of the chip-making carbon footprint to surprise or dismay you. We here at ER Optics are watching the companies creatively self-regulate the industry.

Dark Side vs. Light Side: The Chip Manufacturing Paradox

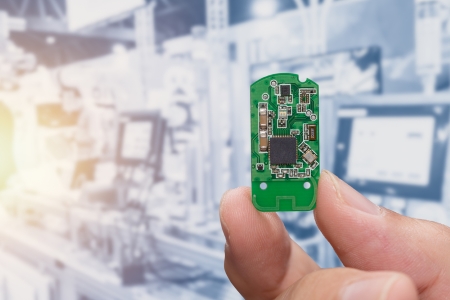

Even the Simplest Chip Must Be Packed With Rich Resources of Water, Air, and Energy.

We know we need the technology produced by the chips. What remains to be seen might be the greatest challenge yet facing humankind. Can we balance our need for technology with transparency and good stewardship of the resources needed to support the industry?

We have applied great ingenuity to creating technology and marketing for great American Chips. Now we must apply the same responsible energy to improving the environmental aspects of creating semiconductors. Otherwise, the dark side of the industry could outweigh the good it brings our culture, humanity, and our planet.

Chip Making vs. the Environment

Previously, we blogged on the complicated steps of the semiconductor manufacturing process. The various steps to build these miniature marvels include:

- “Design.

- crystal processing.

- wafer fabrication.

- final layering.

- Cleaning.

- And assembly.”

And we must add, specialized packaging. Each step requires precision and caution with precious chemicals, raw materials, and procedures.

1. One Aspect of the Dark Side of Chip Making: Resource Usage

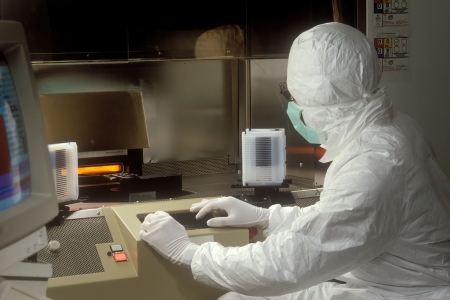

Clean Rooms and Meticulous Research Will Help the U.S. Defeat the Dark Side and the Giant Carbon Foot Print of computer chip manufacture.

Back in 1997, the Silicon Valley Toxics Coalition created a report for the online resource “Corp watch.” The report asserted that the production of every single six-inch silicon wafer consumed an astounding list of resources:

- Firstly, 3,200 cubic feet of bulk gases.

- Twenty-two cubic feet of hazardous gases.

- 2,275 gallons of deionized water.

- Twenty pounds of chemicals.

- And finally, 285-kilowatt hours of electrical power.

Now you know at least part of the reason this industry is so expensive.

2. The Second Facet of the Dark Side of the Chip Industry: Waste

Likewise, we know that for every six-inch silicon a facility creates, they make a certain amount of waste.

- Twenty-five pounds of sodium hydroxide,

- 2,840 gallons of wastewater,

- and Seven pounds of miscellaneous hazardous wastes.

Without mentioning any names or brands, suppose a facility processes 5,000 eight-inch wafers in a week.

By keeping the above figures in mind, you can imagine that there is an environmental cost to be paid. Fortunately, in 2021-22, we have been preparing for a rise in the US chip-making industry. Additionally, American industry also has been quietly discovering and implementing new ways to mitigate the effects of chip manufacture on the environment.

3. Controlling the Air Pollutants: The Third Facet of Our Challenge to the Dark Side

Fortunately, scientists and technologists have already begun to work on the manufacturing issues that affect the air. We are proud to announce that individual corporations both in the US and Taiwan have found ways to combat acid fumes, volatile organic compounds, and toxic gases. As you might realize, developing ways to defeat these ecological challenges are not cheap. (And now, you know another reason the making of chips is expensive.)

4. Creating Chips and Conserving Our Water Resources

Challenge of Chip Making: Balancing Sustainable Development of the Industry With the use of Resources.

One of the largest problems faced by chip manufacturing plants has always been water usage. Likewise, the complex process of chip-making causes the creation of several types of water waste pollutants.

The dark side of chip manufacturing can result in deionized water, solvents, acids, photoresists, waste aqueous metals, and chromium. However, great technological minds are combatting this problem with clean-up procedures and regulations.

In the past, “Due to the hazardous nature of these liquids, semiconductor companies historically have incurred clean-up costs related to groundwater contamination of up to USD 100 million.

ER Precision Optical and Other Responsible Companies Fight Back Against the Dark Side

Thus, never have the words recycle and reuse been more important to the industry. And technologically creative reuse of water has really made the news.

- “Some companies are proactively meeting these challenges and mitigating related risks by reducing their reliance on chemicals…”

- Likewise, some companies are “proactively improving the treatment of water before discharge.”

- STMicroelectronics, for example, recycled and reused 45% of the total water it withdrew in 2015…

- Additionally, Intel favors transparency and reports its water usage and treatment fairly without regulatory compunction.

ER Precision Optical: Meeting Our Nation’s Needs and Protecting Our Environment

Additionally, we need semiconductors for other ecological solutions, like electric vehicles, solar power, and wind turbines. Thus, the paradox is circular. Thus, if chip manufacturing contributes to the ecology crisis, then it is also part of the solution.

Meanwhile, ER Optics is seeing a renewed determination to make the chip industry cleaner, greener and leaner. “The vast demand for chips at the moment will only help the semiconductor industry embrace sustainability goals, said Li, the CEO of TWMC.

Dollars Defeat the Dark Side

Additionally, Proper Development of Chip Technology Can Help Build a Cleaner, Greener, Future.

The US chip-making companies stand to make fortunes as the industry grows. According to recent articles in The Guardian, these companies “have exceptionally good profit margins, and make lots of money. So, even though all these green carbon measures would have a cost, they can afford it.”

Likewise, we have noted that consumers are quite accustomed to paying more money for devices that are cleaner, greener, and leaner. It’s so nice when ethics and economics can complement each other. That’s why the dark side of chip-making will not win.

Now, CEO Li of the Taiwan Semiconductor Manufacturing Company, the world’s largest chipmaker… has pledged “to reach net zero emissions by 2050.”

Moreover, we can perceive that pledge as a friendly challenge. Additionally, if they don’t do it, we have a strong feeling, that a US chip-making company will!