Silicon Semiconductors are no longer secrets in regard to critical importance in our daily lives. Recent shortages have highlighted their essential importance. Indeed, experts have declared silicon semiconductors to be “the building blocks of all modern technology.”

From your car to your refrigerator to your automobile, to your cellphone, you engage these little miracles of technology every day. Thus, it’s time to delve deeper into the secret lives of silicon semiconductors and their effects on 21st-century life.

Recent Shortages and New Manufacturing

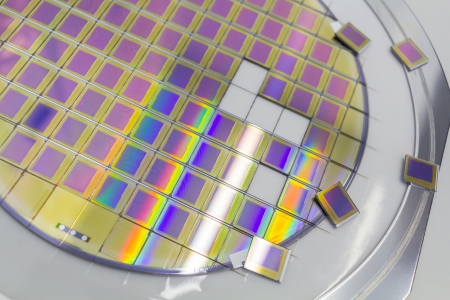

A Large Silicon Wafer is Diced Into Tiny Chips Which Carry the Secrets of the Device they Will Run.

We might actually say we are arriving in the golden age of silicon semiconductors. Most semiconductors use silicon as their base, their substrate, although some semiconductors utilize other materials. Check out our previous article for details on how semiconductors are made.

Thus, as the semiconductor market grew, so did the silicon wafer market. Proof of this is that the “silicon wafer market was valued at USD 9.85 billion in 2019…” However, we expect it to reach 13.64 billion by 2025.

A Time of Opportunity and Obstacles

Our recent chip shortages alerted us how critical this industry is to our technological future. Now, we know how critical the manufacturing of silicon wafers and semiconductors is to 21st-century life.

We learned that painful truth when car manufacturers lost millions of dollars in sales due to the shortage of chips.

In fact, the president of the United States recently held up a silicon semiconductor and stated, “This is infrastructure…” In a manner of speaking, the semiconductor or chip has become a building block of our technology. Additionally, we might consider semiconductors as the cornerstones of technology.

Suddenly the manufacturers of semiconductors are considered essential industries. And likewise, it is clear that we need to build up the semiconductor industry in the US. We must not be so totally dependent on other countries.

The Woes and Wonders of the Semiconductor Industry

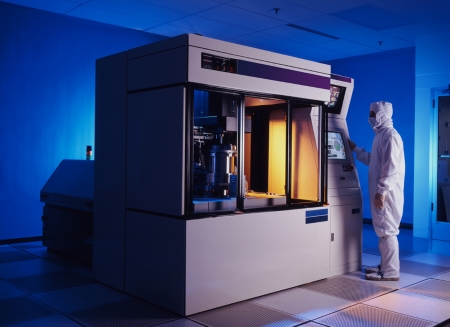

Silicon Wafers in the Immersion Stage-just one of dozens of processes on the way to becoming semiconductors.

Before the end of 2022, we expect the global semiconductor chip industry to reach about US$600 billion.

Sadly, about 80% of these semiconductors come from a small number of manufacturers in an even smaller number of countries. We certainly hope to change that.

Currently, we are seeing the US industry rev up the fabrication of the little chip built on the silicon wafer inscribed with it’s electronic secrets.

The Value of Silicon Semiconductors

The unavailability of a tiny chip “often costing less than a dollar,” can prevent the sale of a device worth tens of thousands of dollars? When we follow that statistic logically, we can estimate the price of the semiconductor shortage over the past two years at about $500 billion dollars.

Additionally, we have had four major disruptive difficulties to overcome:

- the trade war with China.

- the Covid-19 Pandemic.

- the War in Ukraine.

- and supply chain issues.

This does not consider lesser-known difficulties like the flood in Taiwan. It prevented planned shipments of semiconductors from arriving in the United States.

Secrets You Might Not Know from a Silicon Semiconductor Manufacture in Taiwan

“Despite its small geographic size, Taiwan is a global giant in semiconductors. Taiwan Semiconductor Manufacturing Corp (TSMC) supplies 48 percent of the global chip market.”

Furthermore, Taiwan has the world’s largest foundry. It is known as the Taiwan Semiconductor Manufacturing Co or TSMC.

Their client list supports such industries as Apple, Qualcomm, and Nvidia. “TSMC accounted for 54% of total foundry revenue globally last year.” That’s a vast number of semiconductors!

Bloomberg reports “Taiwan’s grip on the semiconductor business — despite being under constant threat of invasion by Beijing — also represents a choke point in the global supply chain.

Making More Semiconductors in the US

And Bloomberg adds the most crucial point that the entire world must become less reliant on TSMC.

There have been recent silicon semiconductor emergencies in the auto industries in countries like the US and Germany. And these shortages have given “new urgency to plans from Tokyo to Washington and Beijing to increase self-reliance.”

The Making of Silicon Semiconductors: Humanity’s Most Complex Machines

We at ER Optics certainly hope to see the US manufacturing making more of its own semiconductors in the immediate future. Just in case you do not quite understand how difficult it is to create silicon semiconductors, we refer you to one of our previous articles.

Plus, we remind you that it takes years and billions of dollars just to build and equip the plant. Here is a brief review of the process:

- “Manufacturing a chip typically takes more than three months…”

- The process “involves giant factories, dust-free rooms, multi-million-dollar machines, molten tin, and lasers.”

- Finally, through multiple steps, the process will “transform wafers of silicon…into a network of billions of tiny switches called transistors.”

These transistors then “form the basis of the circuitry” that will make a phone– or a satellite function.

Trending Now: Expectations for the Silicon Semiconductor Industry

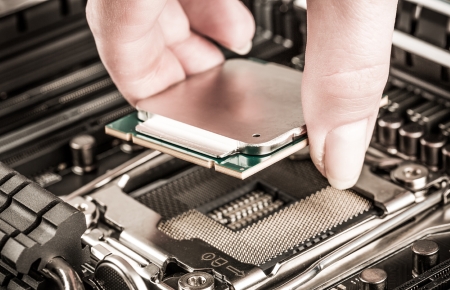

The Processor and Mother Board of Your Computer Would Never Work Without Semiconductors.

Here at ER Optics, our outlook for the future of the silicon semiconductor industry is decidedly optimistic. We are predicting an obvious golden age of vigorous growth.

Likewise, we are aware that the industry faces great challenges and competition. However, we base our optimism on 4 coming trends for the industry and a growing global economy.

-

First: Big Time Growth in the Industry

There will be unprecedented growth in the years ahead. As experts have reported, “We expect the global industry to grow 10% in 2022…” And they add that the market will go “to over US$600 billion for the first time ever.”

To back up this assumption, the demand for silicon semiconductors is continuing to grow. Soon it will embrace all industries. Without the essential semiconductors, there can be no new phones, computers, or data centers.

-

The Continuation of the Supply Chain Snarl

And now, the bad news, because not all current trends are good. We know shortages and those irritating supply chain issues will be with us for some time.

As we go into the second half of 2022, we only hope the situation begins to untangle. However, we have it on good authority that companies anticipate long lead times. Sadly, backorders might even stretch into the end of 2023.

-

A Little-Recognized Shortage: The Talent Shortage

There is a growing shortage of talent to support the chip industry. More people with software skills are critically needed.

Only they can implement the design and integrate the software required by various markets. Thus, “The higher demand for software skills” could exacerbate the shortage.

Naturally, we know the only answer to this shortage is to incentivize workers to attain more training and education in science, technology, engineering, and mathematics. That’s a big challenge for the workers of tomorrow.

-

Last But Not Least: The Digital Transformation and the Silicon Semiconductor Industry

The Digital Transformation is Creating New Methods For Manufacturing at Every Level.

Digital Transformation might not be a phenomenon the average person considers every day. However, it is an ever-changing force in industry and business today.

Thus, let’s look at a quick definition of what it means. “Digital transformation involves using digital technologies to remake a process to become more efficient or effective.”

All over the globe, companies are learning how “to use technology not just to replicate an existing service in a digital form, but to use technology to transform that service into something significantly better.”

Big data, Cloud computing, the Internet of Things, Advanced Robotics, and Artificial Intelligence are all part of the revolutionary changes happening to manufacturing. There are other factors, of course, but those are the big guns.

For any type of manufacturing, Digital Transformation is expensive. Also, it is time-consuming and accelerates every day. In the case of silicon semiconductor industries, it is even more so.

Fortunately, the silicon semiconductor industry as a whole, has a head start in this area. According to experts at Deloitte, “Digital transformation within the industry will continue to accelerate.

Nearly three out of five chip companies have already begun their transformation journey.” However, over half of them are still in the midst of modifying their processes.

Terrific Take-Aways from Silicon Semiconductors

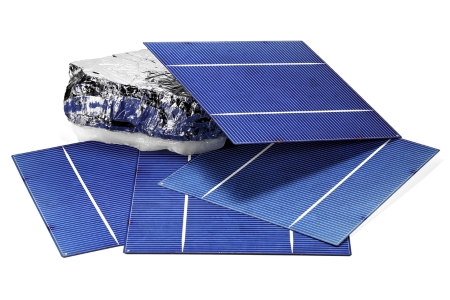

Another Gift From Silicon: Solar Sensitive Cells.

We of ER Precision Optics hope you have enjoyed the insights in this special report on the secret lives of silicon semiconductors and trends in the industry.

We are certain this will not be the last time we write on this critical topic. Since we are Silicon and Germanium specialists, semi-conductors are of special interest to us.

As we say on our products and services page, “E.R. Precision Optical Corporation has invested significantly in our crystal growth facilities. With three crystal pullers, we have more than enough capacity for high-volume orders.

While we specialize in optical grade Germanium and Silicon, we also offer semiconductor or electronic grade and solar grade silicon.”