Energy storage within lithium batteries is changing the ways people think about using silicon. Although it stands on its own, this blog is actually Part 2, based on “Better Batteries With Silicon.” Thus, you might want to read or review our previous blog before continuing to read this one. This one takes a deep dive into the different ways that scientists are manipulating silicon, so it helps batteries work lighter, easier, and less expensively than in the past.

Energy Storage Awakens the New Age of Silicon

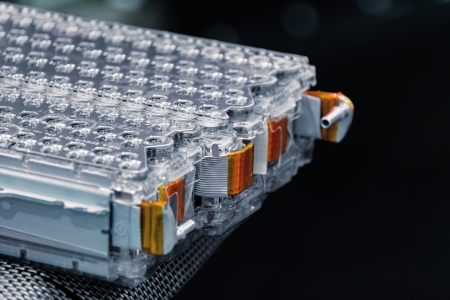

What’s in Your Electric Car’s Battery Pack? Lithion Ions And Maybe a Silicon Anode.

Nanotechnology has taken center stage with silicon, to create new ways to incorporate silicon into automobile batteries. As a result, storing energy in lithium batteries has opened the “Age of Silicon,” as Rick Costantino has dubbed the coming decades.

Let’s take an investigative tour into the technological ways companies are integrating silicon into automobile batteries. And let us keep in mind that the research and manufacturing of batteries including silicon will be responsible for less expensive electric cars in the near future.

A Quick Backstory

In the first place, we cannot resist repeating Costantino’s quote from our last blog. He said, “Silicon has transformed the way we store information, and now it’s transforming the way we store energy.” Our question is how are they doing this? To put our question simply, “How are companies getting silicon into their batteries?” The answer lies in a multitude of new and daring ways.

- Remember, as written in our previous article, Silicon can soak up more lithium ions than graphite.

- Likewise, silicon can send those ions over a battery membrane faster than graphite.

- Furthermore, silicon is quite abundant.

Unlocking the Nanotechnology for Energy Storage with Silicon

Also, however, we must remind you that silicon had some previous problems such as volume expansion. Additionally, it could also cause material fractures. No one wants their anodes to contract, expand or fracture. “…In 1976, before graphite became the compromise solution—silicon’s drastic swelling and shrinking during charge and discharge quickly disintegrated the anode.” It took scientists 15 years to solve these problems.

Improving Energy Storage with Silicon

The Future of Car Design is Electric And Silicon Plays a Large Role in Energy Storage For Those Vehicles.

Battery makers like Tesla simply increased the lithium-holding of anodes by adding a tiny bit of silicon, like 5 percent. Now, many start-up companies are competing to discover new ways to maximize the advantages of using silicon in their batteries. And they are working with nanoengineered silicon to combat swelling and fracturing.

New Ways to Use Silicon in Batteries

Yi Cui and his company, Amprius, commercialized silicon nanowire anodes. In fact, “The company has improved the process to grow nanowires directly from the metal current collector substrate.”

- You see, Amprius discovered that nanowires do not swell up the way previously used spherical nanoparticles do.

- The company also made a smart choice to utilize pure silicon, which is thin and porous. Those silicon features allowed a depleted battery to charge much faster.

Amprius: Astonishing Energy But, Very Expensive Battery Energy Storage

Charged up, the Amprius battery can have an astonishing energy density of 500 watt-hours per kilogram. To give you a perspective on this, your electric vehicle only requires half that much.

Given all these benefits, what could be the possible downside? The process is very expensive. Another problem is that existing electric vehicle battery production companies can’t use Amprius technology.

However, Amprius has possibly found a niche nice market within the air transport and drone industries.

The OneD Company Finds a Sweet Silicon Answer

The OneD Company improved both the nanowires and the processing expense. They infused the nanowires into graphite particles. Their processing is only two dollars per kilowatt-hour. The batteries create energy densities of 350 watt-hours per kilogram and 80 percent charge in 10 minutes. Thus, the OneD Company credits its success to adding the perfect “amount of silicon to EV (electric vehicle) batteries.”

Group 14 and Sila Companies: Compatible Solutions in Energy Storage

Group 14 and Sila are focused on using silicon that highly resembles the black powder graphite we now use standardly for anodes. This design brings the advantage of being very compatible with the existing technology at current battery manufacturing plants.

Hence, the battery makers do not have to redesign the wheel—or rather, the battery.

The secret created by Sila involves a special scaffold around the nanostructured silicon particles. Keep in mind the powder is only micrometer-sized. Thus, the little spaces in the scaffold allow the silicon to swell, but not damage the battery.

And yet, the scaffolding allows lithium ions to travel through it without causing fracturing. The result is a battery that will give your car about 160 kilometers more range than the classic graphite anode battery.

And the ambition of the Sila Company is to “Create enough anode material for 1 million EVs within the next five years.”

Group 14: Injecting Energy Storage with Amorphous Silicon

The Role of Many Research and Development Companies is to Create Electric Cars in Price Parity With Combustion Engines. However, Energy Storage Partially Dictates Price.

From the above examples, we can clearly see that nano-based energy storage with silicon takes many forms. Perhaps the most unique of all is the proprietary process taken by the Group 14 company. They utilize amorphous silicon, which is shapeless and not crystalline.

The Energy Storing Secrets of Group 14

- Group 14 makes micrometer-size, very porous carbon particles.

- Then they zap them with chemical vapor deposition.

- This gets the silicon inside the very pores of the carbon particles within the anode of the battery.

Rick Constantino, CTO of Group 14, states, “Amorphous silicon is the ideal form for energy storage. It’s the most stable form, with high capacity and greater cycle life.”

He also stated that their innovation was grounded in a desire to create a “drop-in technology that works seamlessly with current infrastructure involved with the production of batteries.”

However, Group 14 does not intend to restrict its energy-storing technology to the electric vehicle industry. More than your car, they will power your airplane or any other mode of transportation you care to take.

Taking Energy Storing Beyond Nanostructure

All of the companies above have utilized nano-structuring. However, other companies and universities are researching wild new ways to incorporate silicon into their energy storage solutions.

For example, Enevate, a company in California, uses porous silicon films on copper foil. They found a niche with Lightning Motorcycles, powering electric bikes. They get 220 kilometers of range with a mere 10 minutes on the charger.

NanoGraf: Lighter is Better

The Future of a Cleaner. Greener World Relies Largely on Energy Storage.

For another alternative process, NanoGraf Company pre-swells its silicon oxide material. They are making lightweight battery packs for soldiers to “carry for communication devices and goggles.” No one would deny the value of lighter battery packs.

Terrific Take-Away from Energy Storage: New Ways with Silicon

No matter which company we look at, we know everyone, including the consumer, is seeking the best energy storage for the best price. And at ER Precision Optics, we are pleased that silicon just might provide the best path to this goal.