Capabilities

Capabilities

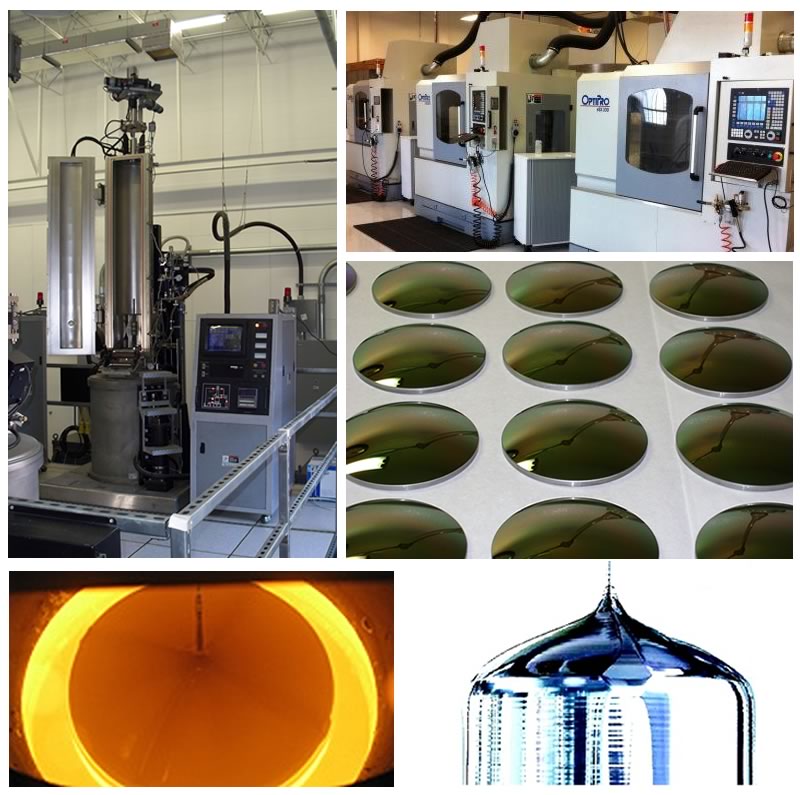

Materials Division

- Full custom Germanium & Silicon crystal growing capabilities.

Blank Fabrication Facility

- Multiple OptiPro 5-axis CNC machining centers

- Meyerburger Precision CNC saw

- Blanchard grinders

- Core drilling

- Centering & Edging

Polishing

- OptiPro High Speed CNC Polisher

- OptoTech Sp30 for dome polishing

- Continuous polishers 2 – 72inch and 2 – 48inch

- Multiple spindles for grinding, polishing of radius & flats

- Full range of all optical coating requirements

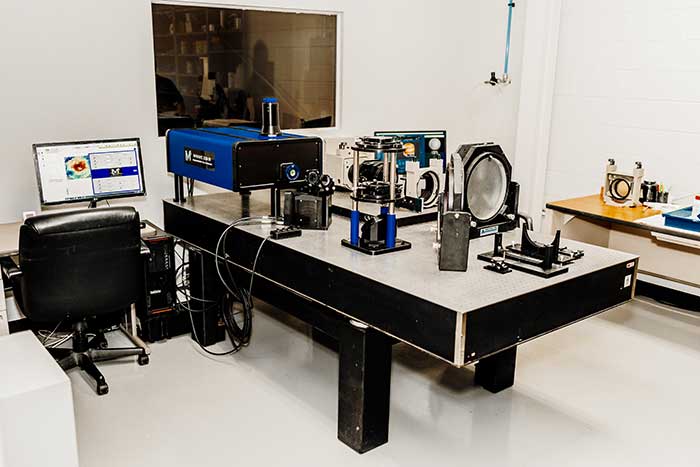

Metrology

E.R. Precision Optical is proud to stand behind our products from the finest quality materials to finished optical components. We assure our customers of this quality with the rigorous tests and measurements on all our shipments. We utilize the most highly recognized equipment in the industry to test all our finished parts.

ERPOC has a full line of tooling in-house to validate your critical specifications on materials and products:

- MWAVE339 Interferometer – 3.39µm

- MWAVE Refractometer (Index of Refraction / Homogeneity)

- Transmission and Reflectance -Perkin Elmer FTIR Spectrophotometer

- Material resistivity – (≤ 0.1 Ω cm) Micro Circuits 4-pt Probe

- Surface roughness – (≤1 Å) Zygo Profilometer

- Surface irregularity & radius of curvature – ( ≤ λ /10)

- 2 Zygo Interferometers — .632µm

- Angular deviations – (≤1 arc second)

- Nikon Auto Collimators

- Nikon measurescope 20

- Concentricity or (TIR) Total Indicator Runout – (≤1 second)

- Opto-Alignment Assembly Station

- Keyence VR-3200 hi-speed wide-are 3D measurement system

Upon request with your purchase order, ERPOC will provide Certifications of Compliance and/or Coating Curves to your material, optical performance and dimensional specifications.

Thorium Coating Removal Center

- Licensed by State of Florida, Department of Health, and Bureau of Radiation Control to remove radioactive coatings from Germanium in our demilitarization / recycling process.